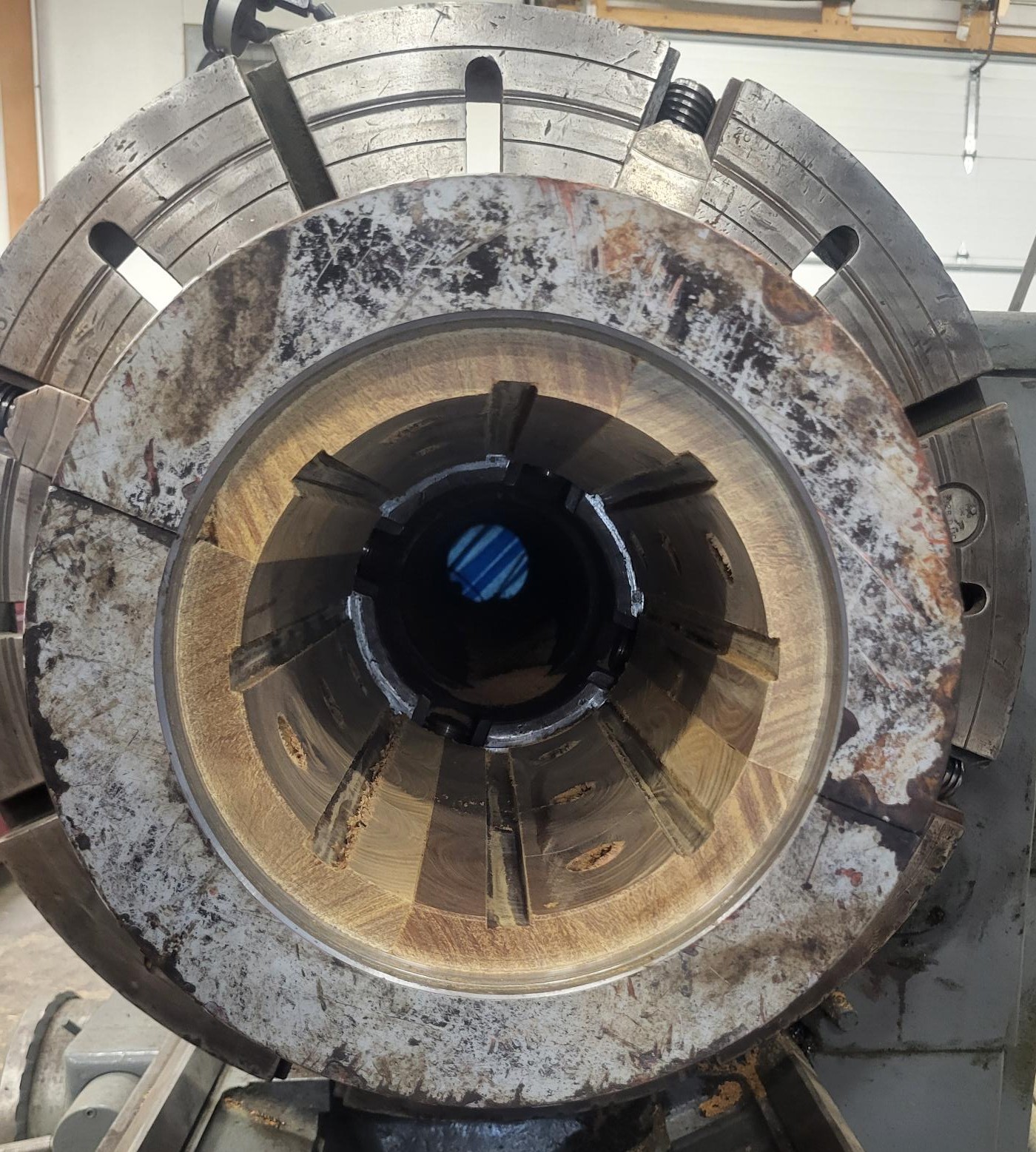

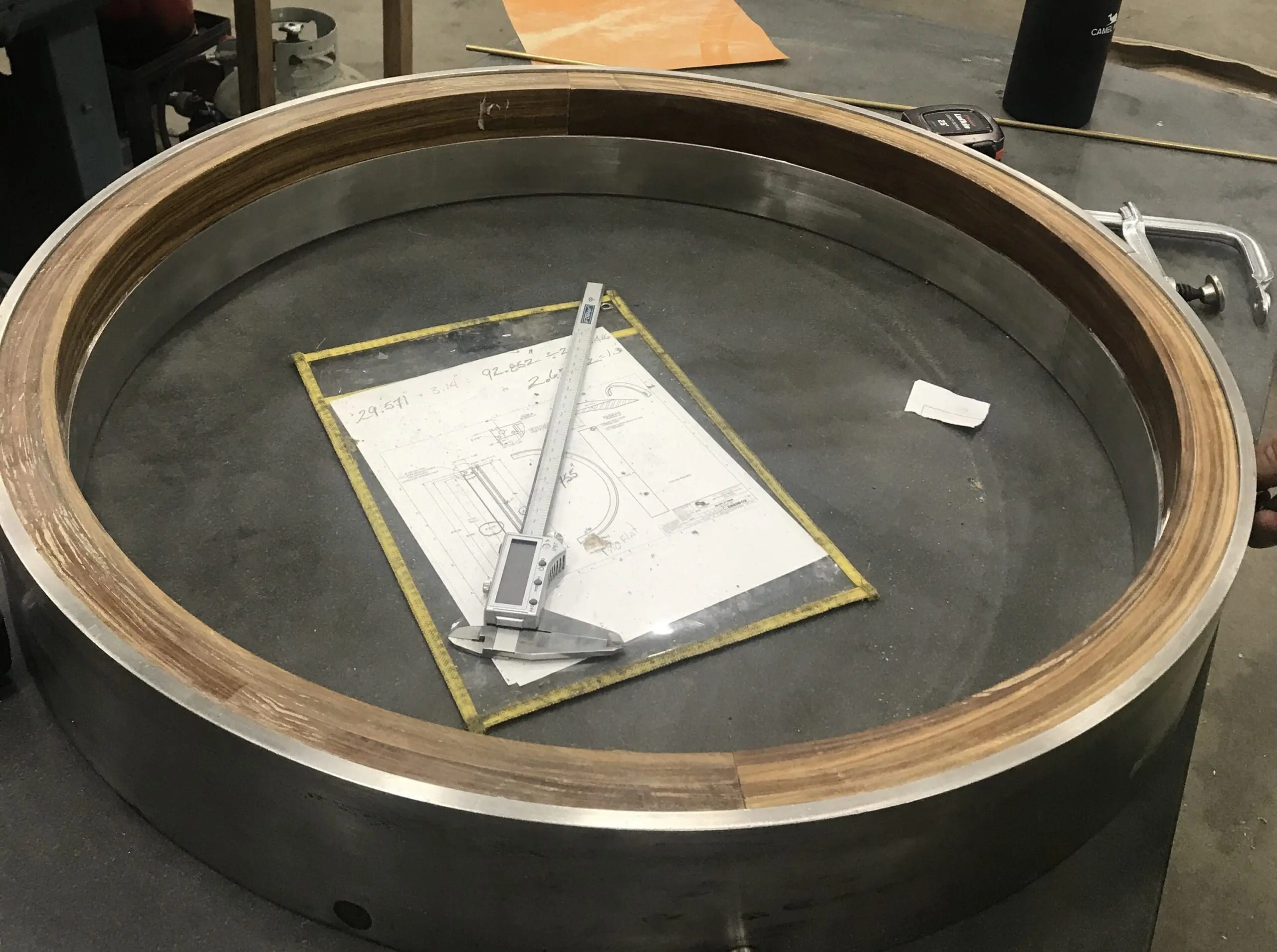

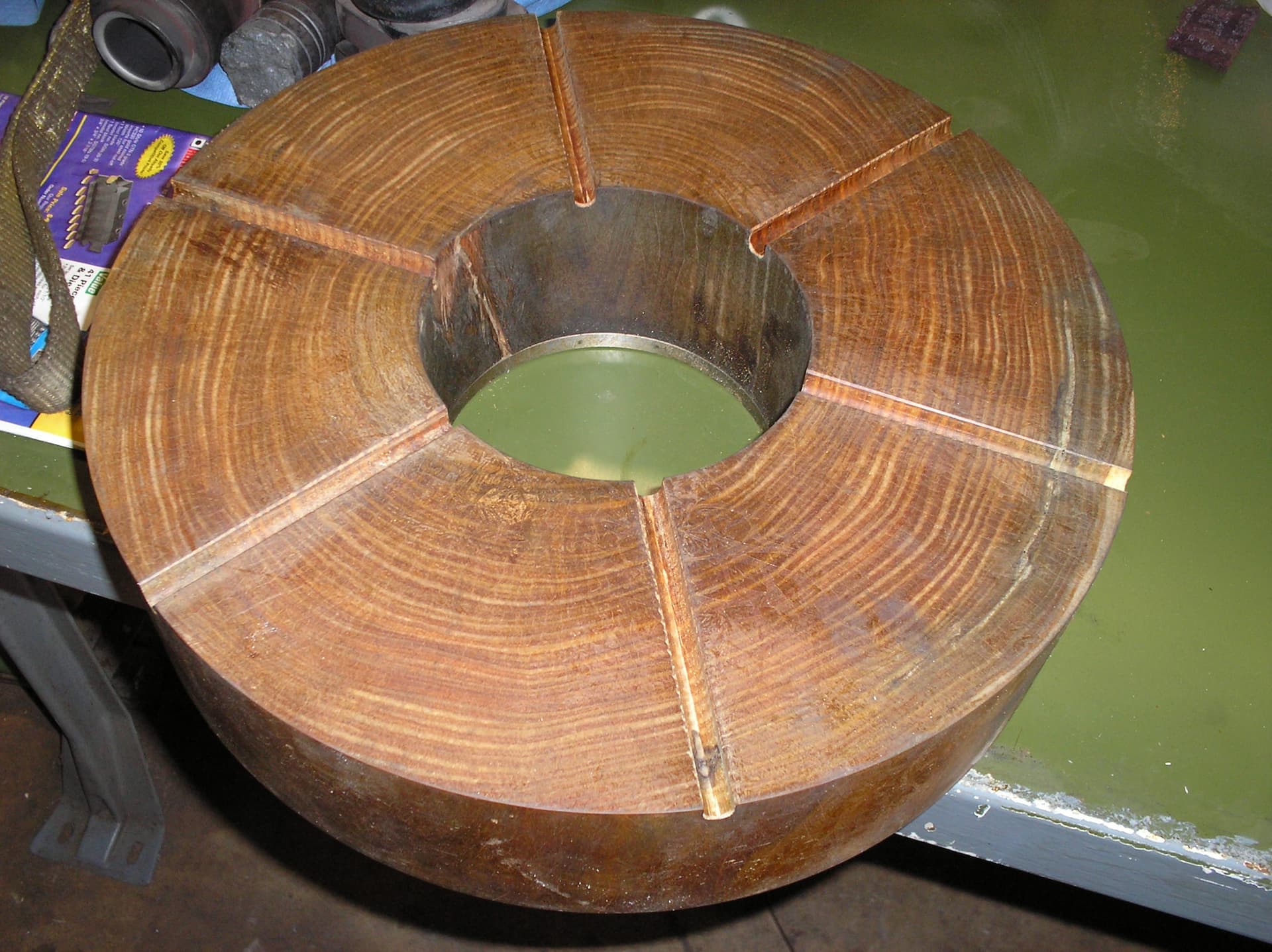

Product Gallery

Lignum Vitae Bearing Solutions: The Natural Advantage

Lignum Vitae offers custom-engineered bearing solutions for demanding applications across hydro, marine, and industrial sectors. Crafted from the world’s densest ironwood, our bearings provide superior performance, longevity, and environmental responsibility compared to conventional materials like composites, plastics, and oil-lubricated metals.